Locating the Right Provider for Welding Inspection Madison: Key Considerations

Locating the Right Provider for Welding Inspection Madison: Key Considerations

Blog Article

Comprehending the Principles of Welding Inspection to Make Sure Quality and Security

In the world of modern-day engineering, welding inspection stands as a foundation for making sure both the high quality and safety of architectural developments. What are the nuances of these assessment methods that make them crucial for preserving architectural integrity?

Importance of Welding Evaluation

In the realm of industrial construction, the value of welding evaluation can not be overstated. Welding assessment plays a crucial role in ensuring the honesty, security, and longevity of bonded structures (Welding Inspection Madison).

The process of welding naturally involves intricate variables, consisting of temperature, product residential or commercial properties, and environmental problems, all of which can affect the high quality of the weld. An extensive inspection recognizes flaws such as cracks, porosity, and insufficient blend, which can jeopardize the strength and integrity of the weld. By finding these concerns early, rehabilitative activities can be taken, consequently lowering the threat of failing and connected prices.

In addition, welding evaluation contributes to regulatory conformity, as several markets are controlled by rigorous security standards and guidelines. Failure to stick to these regulations can cause financial charges and lawful responsibilities. Ultimately, welding assessment not just safeguards physical structures however likewise maintains and shields human lives industry reputations.

Trick Welding Inspection Methods

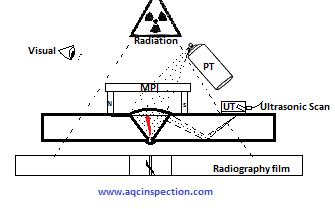

Although welding assessment is essential to making sure the top quality and safety and security of bonded structures, it is the particular techniques used that establish the effectiveness of the assessment procedure. Key welding evaluation techniques can be extensively categorized into non-destructive testing (NDT) and harmful screening. Non-destructive screening techniques such as aesthetic assessment, ultrasonic testing, radiographic screening, magnetic particle screening, and fluid penetrant testing are largely utilized to review the residential properties of a weld without triggering damage. Aesthetic inspection is often the initial step, including a detailed exam of the weld's surface area for defects like fractures or porosity.

Magnetic fragment screening and liquid penetrant screening are surface area examination methods used to find surface and near-surface problems. These extensive inspection methods make sure that welds satisfy industry criteria and security needs, thus ensuring structural integrity and performance.

Role of Certified Examiners

Certified examiners play a pivotal function in the welding inspection procedure, making certain that all welds adhere to rigid industry standards and safety guidelines. Their competence is vital in identifying flaws or irregularities that may endanger the structural stability of a weld. By carefully analyzing each weld, certified assessors assist protect against potential failures that can cause pricey repair services or dangerous crashes.

To come to be licensed, assessors should undertake rigorous training and screening, which familiarizes them with different welding strategies, materials, and testing approaches. This extensive knowledge allows them to examine weld quality efficiently and make informed judgments regarding their security and reliability. Qualified inspectors are skillful in analyzing plans and requirements, guaranteeing that the welding job lines up read this article with the project's layout demands.

An important part of their function is to record their findings completely, providing an in-depth document of the examination procedure. This documentation is crucial for traceability and accountability, functioning as an official record of conformity with market criteria. Licensed examiners likewise play an essential function in helping with communication between task stakeholders, supplying understandings and referrals to improve welding methods and results. Their payment is indispensable in maintaining high degrees of quality and security in welding procedures.

Devices Utilized in Welding Assessment

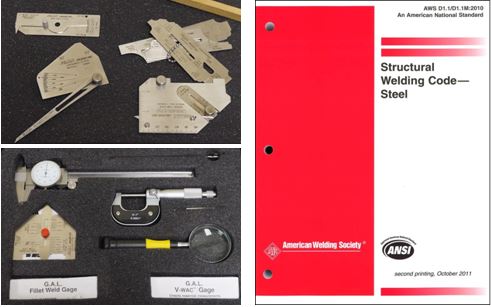

Welding examiners rely upon a variety of specialized tools to execute their tasks effectively, making sure each weld fulfills the essential requirements. Amongst these tools, visual evaluation help like multiplying glasses and mirrors are fundamental, permitting assessors to very closely examine welds for surface defects such as cracks, porosity, and undercut. Calipers and fillet weld gauges are necessary for determining weld measurements to confirm conformity with design requirements.

Advanced devices extend past aesthetic help, consisting of non-destructive check this screening (NDT) tools. Ultrasonic screening devices are essential in finding subsurface problems, utilizing audio waves to reveal inner interruptions without endangering the weld's stability. Radiographic screening uses X-rays or gamma rays to capture pictures of a weld's interior, highlighting possible problems.

Magnetic fragment testing is one more vital tool, especially for identifying surface and near-surface stoppages in ferromagnetic materials. By applying magnetic fields and ferrous fragments, inspectors can recognize flaws that could or else be undetectable.

Dye penetrant inspection is usually utilized for non-ferrous products, providing a contrast-enhanced visual check for surface-breaking flaws. Welding Inspection Madison. With each other, these devices allow welding inspectors to adequately assess weld high quality, guaranteeing safety and dependability in various applications throughout industries

Guaranteeing Structural Integrity

Welding procedures need to adhere to well-known requirements and codes, such as those specified by the American Welding Society (AWS) or the International Company for Standardization (ISO) These standards make certain that the welds can endure operational anxieties and environmental variables. Qualified and accredited welders play an essential duty in this procedure, as their experience guarantees that strategies are applied properly, reducing problems such as cracks, porosity, and insufficient blend.

Post-weld inspection is another vital component of confirming structural stability. These assessments confirm that the welds meet the needed quality criteria, supplying assurance of their longevity and dependability.

Conclusion

The basics of welding inspection are necessary for maintaining the top quality and web safety of welded frameworks. The use of specialized devices further enhances the inspection process, eventually protecting human lives and lengthening the life-span of bonded buildings.

Welding assessment plays a crucial duty in making sure the integrity, safety, and durability of bonded structures.Although welding examination is important to ensuring the quality and safety and security of welded frameworks, it is the specific techniques employed that establish the performance of the examination process. Key welding assessment approaches can be broadly categorized right into non-destructive testing (NDT) and destructive screening.Qualified inspectors play a critical role in the welding evaluation process, guaranteeing that all welds abide with rigorous sector criteria and safety regulations.The principles of welding assessment are necessary for maintaining the high quality and safety of welded structures.

Report this page